What are the common pipette handling errors?

Improve your pipetting technique

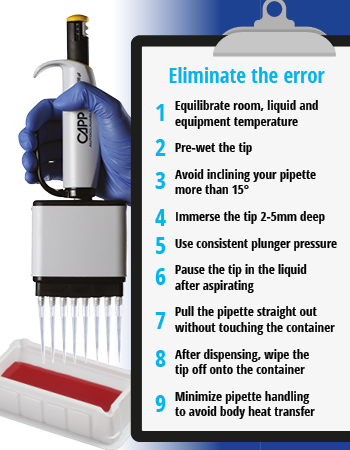

Many pipetting errors can be traced to poor pipetting technique. When users develop their pipette handling skills the incidence of pipetting error may reduce dramatically.

Many pipetting errors can be traced to poor pipetting technique. When users develop their pipette handling skills the incidence of pipetting error may reduce dramatically.

One quick way of setting yourself up for good pipette technique is selecting an ergonomic pipette such as the CAPP ecopipette. Using an ergonomic pipette reduces discomfort and primes you for successful pipetting.

Additionally, we recommend working in a stable lab environment to minimize the chances of random error. When selecting pipette tips, quality matters. Relying on high quality pipette tips will always reduce pipetting error and help you improve your pipetting technique faster. It also helps to learn to identify the different types of pipettes and select the best pipette for the job.

The article below gives some helpful tips for reducing pipette error and improving your pipetting technique. For more tips, check CAPP’s helpful Lab Everyday guides.

Find proper technique and eliminate the sources of error in pipetting

Establishing good technique is one of the most effective ways of eliminating pipetting error. By learning good pipetting technique, scientists and lab technicians can learn to recognize sources of error in pipetting, leading to better outcomes for their research work and diagnostic assays. In this article, we will explore some common sources of error in pipetting and offer suggestions for improving your own pipetting technique. We recommend bookmarking this page on your browser so that you can easily refer back to it in the future. As with any new skill, reading is not enough and we strongly recommend taking time to practice with a reliable pipette. That way you will be able to map theory to practice and reduce pipette error while improving both the accuracy and precision of your measurements.

Establishing good technique is one of the most effective ways of eliminating pipetting error. By learning good pipetting technique, scientists and lab technicians can learn to recognize sources of error in pipetting, leading to better outcomes for their research work and diagnostic assays. In this article, we will explore some common sources of error in pipetting and offer suggestions for improving your own pipetting technique. We recommend bookmarking this page on your browser so that you can easily refer back to it in the future. As with any new skill, reading is not enough and we strongly recommend taking time to practice with a reliable pipette. That way you will be able to map theory to practice and reduce pipette error while improving both the accuracy and precision of your measurements.

What are some common pipette handling errors?

There are several pipetting errors that many scientists are unaware of, that can be corrected with proper pipette technique.

There are several pipetting errors that many scientists are unaware of, that can be corrected with proper pipette technique.

The first of these pipetting errors is pipetting too fast as this may result in systematic error. Applying calm and steady pressure on the plunger helps maintain the flow of liquid through the tip, reducing the chances of pipetting error.

Another pipetting error that is common in labs is holding the pipette at an angle. Holding the pipette at an angle reduces the effective hydrostatic pressure on the sample volume.

Handling your pipette in a vertical position is the ideal and this reduces the incidence of pipetting error. Another common pipetting error is a failure to prewet pipette tips.

Prewetting pipette tips allows the air cushion to equilibrate to the liquid volume to be aspirated. To avoid this pipetting error we recommend inserting the tip not too deeply into the liquid and holding it there for ≈3 seconds before aspirating. For even better results, we recommend using premium quality pipette tips that are designed to reduce pipetting error.

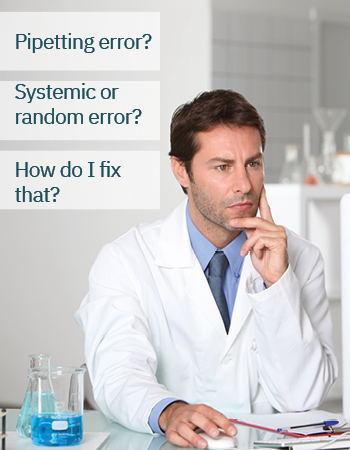

Systematic error vs random error in pipetting

Two types of pipette error often cited in quality standards may affect piston pipettes. Being aware of the difference between both types of pipette error may help you keep your measurements truly accurate.

Two types of pipette error often cited in quality standards may affect piston pipettes. Being aware of the difference between both types of pipette error may help you keep your measurements truly accurate.

The first pipette error is commonly referred to as systematic error. Systematic error refers to a consistent difference between the volume selected by the user (nominal volume) and the volume that they dispense.

To determine systematic error in a piston pipette, the ISO standard ISO 8655-1:2002(en) recommends using the average of 10 measurements.

The second pipette error, random error, is a statistical measure that summarizes the potential fluctuation in pipetted values because of chance events that may not be replicable every time.

These include fluctuations in the pipetting environment, slight changes in the pipette, or inconsistencies in how the volume is read by the user. To determine random error, the average of 10 repeat measurements of liquid is calculated and the scatter of these measurements is determined.

The larger the systematic error or random error, the less accurate your pipette will be.

Frequently Asked Questions

The uncertainty of measurement of a pipette is a probabilistic value that is used to describe the potential range of measured values that the pipette dispenses around a defined volume. Uncertainty can also be defined as a statistical measure of the dispersion of aspirated values around a predefined value of dispensing. Uncertainty is internationally denoted by a positive value and is usually declared by the manufacturer for the benefit of end-users of the pipette. Uncertainty comes from several sources including calibration accuracy, speed of aspiration, failure to prewet the tip, environmental temperature, and user error among others. At CAPP we prioritize accuracy in all our instruments and as such we always indicate the uncertainty of each of our pipettes.

The error of a pipette is an abstract concept that cannot be determined in real world pipetting environments. It is defined as the difference between the measured value and the true value. If a pipette user measures 1002 µL with their automatic pipette when they intend to measure 1000 µL, the error would be 2 µL. However, as it is not possible to accurately determine the error of a pipette manufacturers prefer to use the concept of uncertainty to approximate pipette error. Uncertainty is a probabilistic value that gives a degree of confidence that the true value of a measurement lies within the uncertainty range. Manufacturers often publish the uncertainty of a pipette on the actual device to guide users on the error of the pipette.

Instrumental error is a term that is used to describe pipettes that are not accurate. If a user selects a pipette to transfer x µL of sample and they end up transferring y µL, this is referred to as instrumental error. Although there are acceptable ranges of pipette error, most cases of instrumental error exceed the acceptable norms and result in inaccurate volume transfers that may lower the reliability of experimental results. Some of the causes of instrumental error are poor calibration, poor quality pipettes, poor pipette handling (dropping or jamming pipettes), and a lack of maintenance among others. To minimize the chances of instrumental error it is crucial that you only use premium quality pipettes that are truly accurate and truly robust. CAPP pipettes are quality controlled to minimize the incidence of instrumental error and provide excellent results each time.

Manufacturers usually publish data on the systematic error and random error of their pipettes. At CAPP, all our pipettes are supplied with technical documentation that specifies the systematic error and random error values of the pipette. This technical documentation is available in the packaging and can be easily accessed by visiting the CAPP website and navigating to the product page via the intuitive menu. It is important to note that systematic error may be denoted as inaccuracy while random error may be designated imprecision in some product literature. Click here to see an example of such technical information can be seen on the specification chart for the CAPPTrio fixed volume pipette available. At CAPP, we make checking the error of your pipette as easy as possible to foster an environment of transparency and trust.

As there are different pipette brands and makes, it is necessary to provide quality guidelines that inform manufacturers and users of what constitutes a good quality pipette. Standard of error provides a framework for everyone to easily determine the quality of a pipette. Standard of error also reduces the incidence of pipette error owing to the irresponsible manufacture of poor-quality pipettes. At CAPP, we approach standard of error a little differently by making sure that we adhere to more stringent nominal values of pipette error. By committing to a higher standard of error, we can provide users with premium quality pipettes and pipettes tips with the some of the best ratings for lowering pipetting error. Standard of error helps pipette users to hold manufacturers like CAPP to high standards of accuracy and precision.

Pipetting error is common in many laboratories and by knowing the sources of pipette error, you will be better prepared to avoid them. One common source of error is using an incorrect pipette (or tips) for your liquid sample. Our article on piston pipettes provides some excellent insight on how to reduce this source of pipetting error. Another source of pipetting error that is often encountered is working with pipettes that are not ergonomic. This is compounded by pipetting for extended periods of time without rest, resulting in variable measurements. Choosing an ergonomic pipette lowers the risk of inaccurate volume transfers. It is also important to pipette at a slow, constant speed. Fast pipetting speed is also a huge source of error leading to inaccurate sample transfers. Using an electronic pipette like the CAPPMaestro single channel pipette may help eliminate this source of pipetting error for newbies and experts alike.

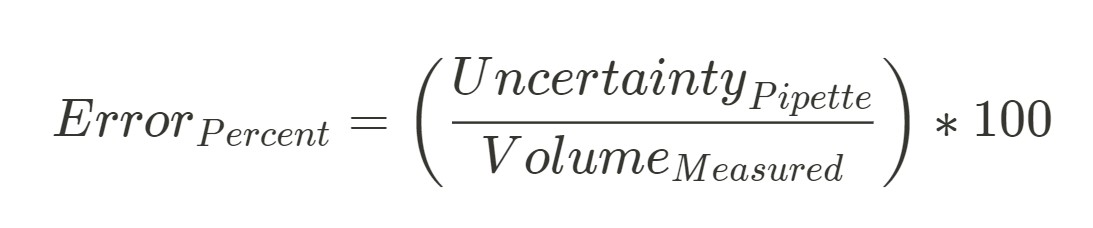

Calculating percent error in pipetting is a simple process that is easy to accomplish in a few steps. As most modern pipettes such as the CAPPMaestro single channel pipette feature a manufacturer specified uncertainty value, this value is what you will reference for your calculations. The uncertainty is also referred to as the error of the pipette and as such percent error may also be referred to as percent uncertainty. The formula for calculating percent error is illustrated below. For example, the percent error for a 1000 µL pipette with an uncertainty of 0.8 would be 0.08%.

To calculate error for a pipette, you would need to know two values. The first is the measured value and the second is the true value. The true value of a measurement is a theoretical approximation that cannot be determined in real world pipetting operations. The measured value on the other hand is a real-world value that most likely differs from the true value. The formula for calculating error for a pipette is illustrated below. It is important to remember that this formula represents an abstract concept that is not possible to determine in the real world. However, with this formula it is possible for scientists and technicians to approximate the error for a pipette.

Another important concept to highlight is the Z factor as this is directly relevant to calculations of pipette error. Calculating pipette error depends on measuring calibrated pipette volumes. The Z factor is a conversion factor used to calculate the measured volume that a pipette transfers. This factor derives from the density of water, and it is also a function of temperature and air pressure. The measured volume is pipetted onto a balance where it is recorded in µg and this value must be multiplied by the Z factor to get the correct reading in µL. A failure to account for the Z factor in your pipette measurements may account for pipette error.

As there are several types of pipettes supplied by different manufacturers, it is necessary to provide guideline ranges for systematic error and random error. The International Organization for Standardization (ISO) published the first such guideline in 2002, ISO 8655-2:2002(E), to provide a common framework for both users and manufacturers to understand the minimum quality standards of pipette error. These guidelines also indicate the maximum permissible pipette error values of a good quality pipette. From this standard, the average percentage error of a good quality pipette (range 1 – 10,000 µL) is 1.55% (systematic error) and 0.95% (random error). At CAPP, we hold our pipettes to higher standards and our pipette error values are more stringent than the ISO recommended limits. CAPP pipettes are truly accurate, truly robust.

Systematic error can be linked to the pipette (innate) or the user. The best way to avoid innate systematic error is to purchase premium quality pipettes from reputable manufacturers. Additionally, regular servicing of your pipettes helps minimize systematic error. User-centric systematic error can be avoided by routine testing and improving one’s pipetting technique. You can test your own systematic error by pipetting ten replicates of a fixed volume of distilled water on a calibrated balance. Calculate the relative standard deviation (standard deviation expressed as a percentage of the mean) of the ten values to get your pipetting error. With this knowledge, you can then implement good pipetting technique and frequently test if your systematic error is reducing. Additional practices such as storing pipettes in a vertical position and using filter tips when transferring corrosive liquids further reduce the incidence of systematic error in your laboratory.

Large-volume micropipettes such as a 1000 µL pipette should meet certain quality requirements to be considered accurate. ISO 8655-2:2002(E) guidelines indicate that the systematic error for a 1000 µL pipette such as the CAPPBravo B1000-1 should not exceed ±0.8% or ±8.0 µL for the pipette to be considered in spec. Similarly, the random error for a 1000 µL pipette should not exceed ±0.3% or ±3.0 µL. Knowing the maximum permissible pipette error helps scientists and technicians to calibrate their pipettes correctly. All CAPP pipettes are designed to meet and exceed the ISO 8655 guidelines, providing users better accuracy and precision for each liquid volume transfer. For example, the CAPPBravo B1000-1 is a 1000 µL pipette with a systematic error of ±2.0 µL and a random error of ±0.6 µL.

If a pipette user does not use correct technique, they are likely to end up with inconsistent volumes owing to pipetting error. A range of pipetting errors may result from poor pipetting technique. The first is systematic error or inaccuracy in measured volume. Systematic error describes a discrepancy between the pipetted volume and the intended volume (nominal volume). Another type of pipetting error that could result is random error or imprecision. Random error describes a pipetting error in which the reproducibility of a transferred liquid volume is low. Aspirating too fast or pipetting volatile liquids may also introduce error is the liquids contaminate and potentially corrode the interior of the pipette. Once corroded, the pipette error may increase, reducing the reliability of the pipette. Using quality filter tips when pipetting protects your pipette from getting exposed to potentially harmful liquids. For larger pipettes, CAPP’s pipette cone filters reduce pipette error resulting from splashes into the interior of the pipette shaft. Although there are many sources of error in pipetting, poor pipetting technique is the easiest to correct through training and practice. It would also help to invest in premium quality pipettes that reduce the sources of error in pipetting.