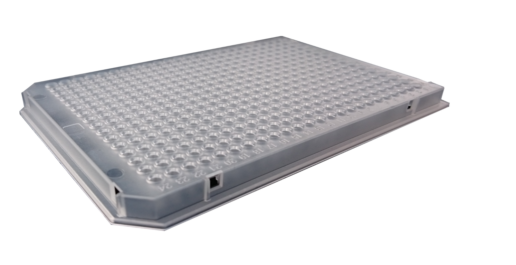

384 well qPCR Manual Pipetting. Changing from 96 to 384 well qPCR

96 well vs. 384 well qPCR

The difference between the 96 and 384 well qPCR is simpler than it may seem: by 384 well qPCR you can go down to 10µL volume and increase the number of your samples within one plate. The principle remains the same.

The Challenge

The challenge by 384 well qPCR may be the planning. By 96 well qPCR you can easily operate with an 8- or 12-channel pipette, as the size of the plate is 8×12 wells!

When switching to a 384-well plate, being 16×24 wells, a standard multichannel pipette is not sufficient, unless you pipette only into every second well. This is neither efficient nor comfortable on a longer term.

An automated liquid station would be ideal for 384 well qPCR, though here you may meet some of the common entry barriers:

• Is there a budget for this?

• Is there a throughput for it?

• Are there skills in place to operate the equipment?

Solution

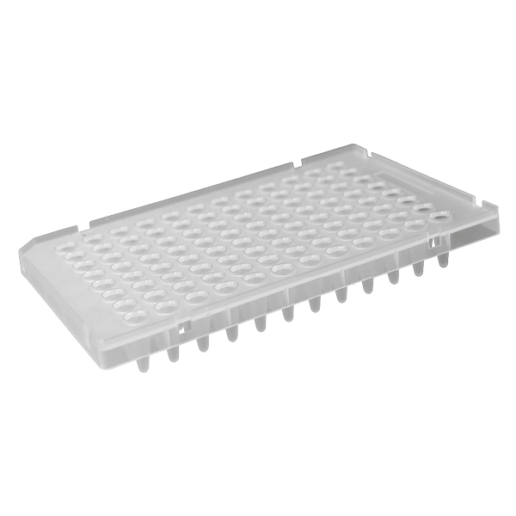

The solution can be simpler as you imagine – a 384 well qPCR manual pipette! Starting with the 16-channel pipette, with which you can take 1 row at a time, through a 48-channel pipette – to take up 3 rows at a time, up to a 64-channel pipette, enabling you to process the whole plate in 4 pipettings only.

Optimizing Workflow by 384 well qPCR and many other applications

384 well manual pipettes are not only ideal by 384 well qPCR but can also optimize applications such as microarrays, genotyping, kinetic studies, MALDI spectrometry techniques and many more protocols conducted on 384 well plates.

384 well manual pipettes are not only ideal by 384 well qPCR but can also optimize applications such as microarrays, genotyping, kinetic studies, MALDI spectrometry techniques and many more protocols conducted on 384 well plates.

Fitting many laboratories’ needs and budgets, the 384 well manual pipettes feature smooth and precise volume adjustment, durable aluminum nozzles providing universal chemical resistance and minimizing the risk of breakage. Moreover, the ergonomics have been a highly addressed factor. Thanks to the comfortable tip ejector lever, the force needed to eject tips has been reduced by 70%.

384 manual pipettes are an inexpensive alternative for expensive robotic plate handling equipment, are great for manual one-off plate filling when using the automated system does not make sense, or just as a backup unit for when the system is down for maintenance or repair.